Why choose Ranken for your degree?

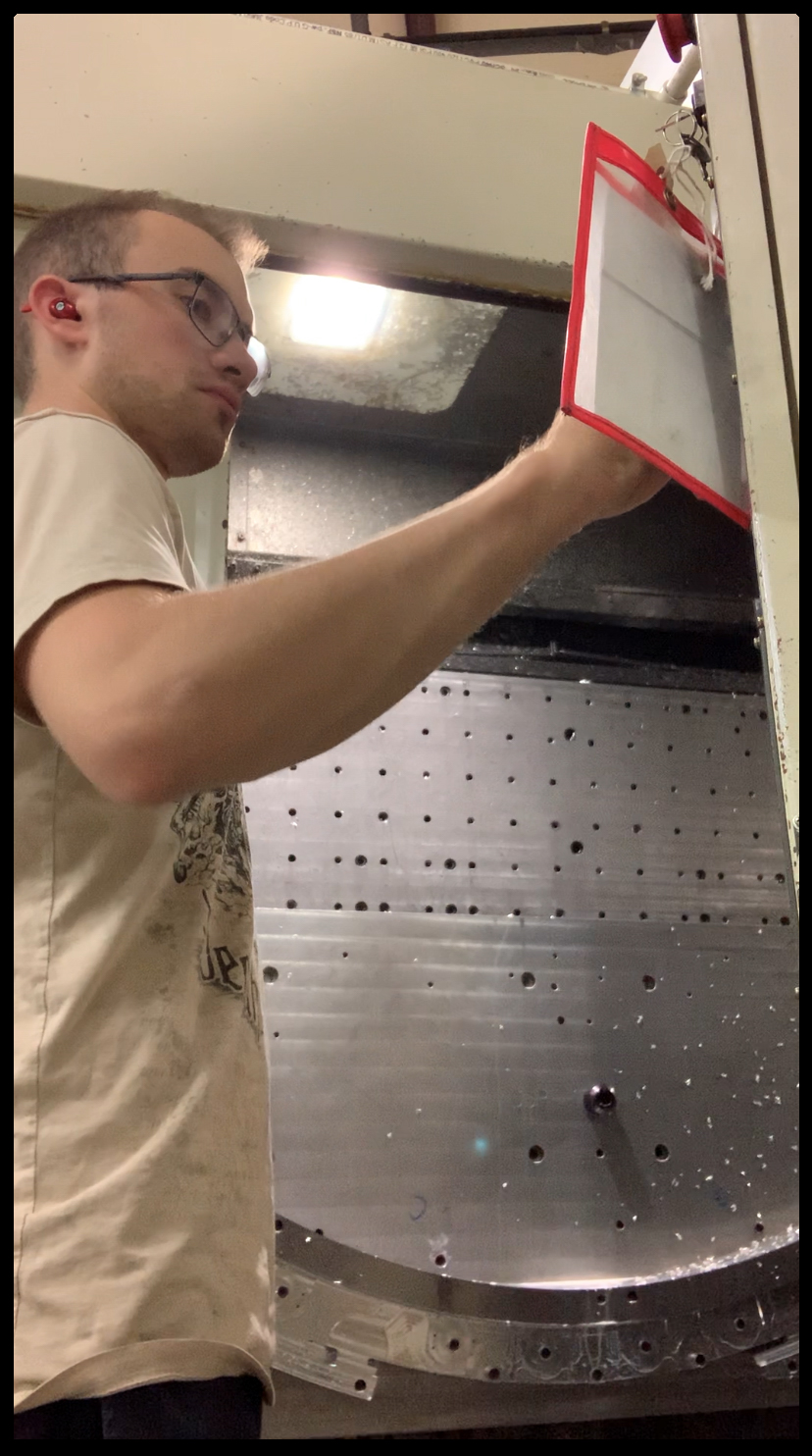

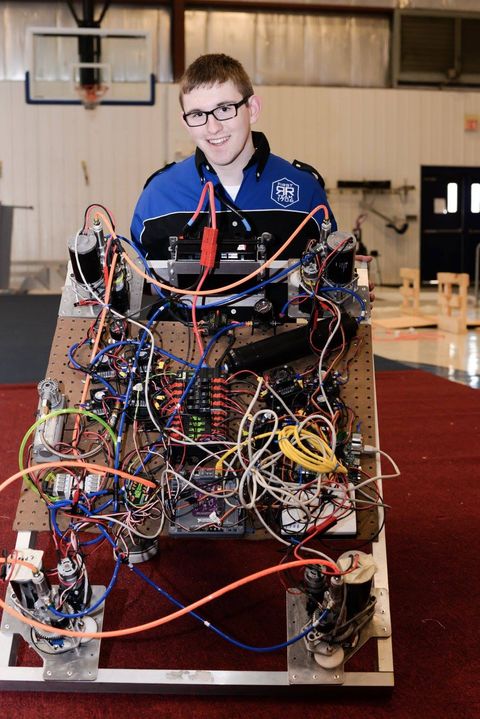

In Ranken’s five-semester Mechanical Automation Technology program, students take coursework designed to prepare them to maintain and repair factory equipment and other industrial machinery.

The four-week classes alternate with a four-week internship to provide real-world experience. Students also take general education courses to complete the degree.

Students at Ranken are introduced to concepts through online multimedia training modules, then practice these concepts on shop simulators to gain hands-on experience. After four weeks of training, students move on to the paid internship, to gain a deeper understanding through real-world experience.

Ranken’s blended technical education offers a superior training program, and the opportunity to “earn while you learn.”

Interested in seeing more of our Mechanical Automation Technology facilities? Take an interactive 360° virtual tour of Ranken Technical College’s MECHANICAL AUTOMATION TECHNOLOGY department.

National Institute of Metalworking Skills (NIMS) Credentials

The industry uses NIMS credentials to recruit, hire, place, and promote workers. NIMS certifies individual skills against a national standard. Earning NIMS credentials requires performance and theory tests, drawn directly from the NIMS Standards, and are written and piloted by industry.

Companies currently Participating in IET internships:

- Beckwood Corporation

- CSC Missouri

- Emerson Electric Co.

- Gilster-Mary Lee Corp.

- H-J Enterprises

- Hussmann Corp.

- Midwest Sterilization Corp.

- P2 Mission Solutions

- Progressive Recovery Inc.

- Red Bud Industries

- Roeslein

- Spartan Light Metal Products

- SRG Global

- SSM Health

- TG Missouri

- Vanderlande

- Washington University/BJC Hospitals

Interested in seeing more of our Electrical facilities? Take an interactive 360° virtual tour of Ranken Technical College’s ELECTRICAL departments.