Is welding school right for you?

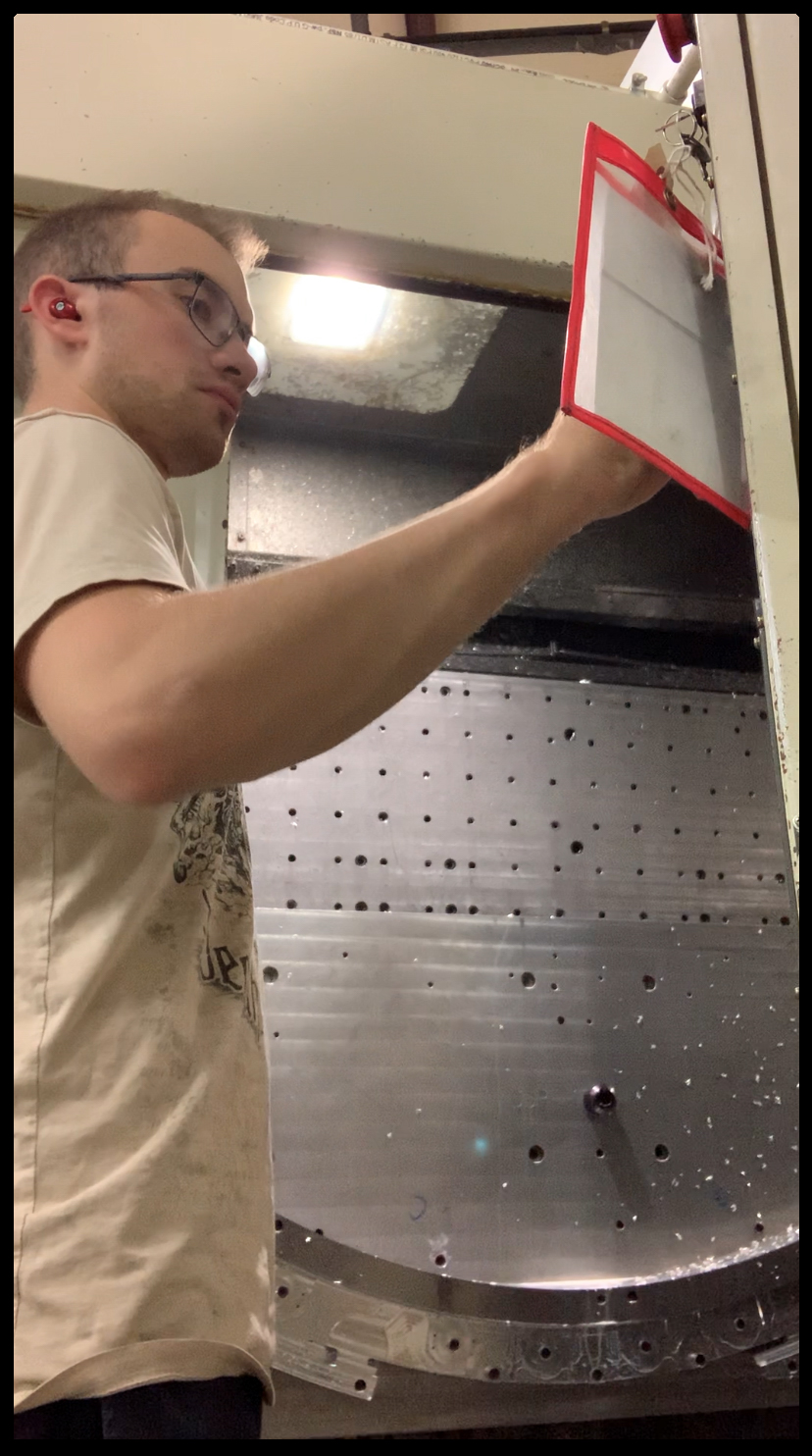

The best career for you would involve hands-on, physical work. You’d rather do a job that involves some heavy lifting than get stuck sitting in one place every day.

You want to learn skills that will give you the flexibility to work in a variety of industries throughout your career – including construction, car racing, aerospace or manufacturing.

Working in a variety of environments sounds good to you. You’ll go where the work is – whether it’s indoors or outdoors, on scaffolding or in small spaces, you get the job done.

Does this sound like you? If so, a welding trade school could be the path to a successful and rewarding career.

The Bureau of Labor Statistics predicts good job opportunities for skilled welders with up-to-date training. Ranken’s two-semester Fabrication and Welding Technology program trains students on essential welding processes, using state-of-the-art equipment in the new Mary Ann Lee Technology Center.

Interested in seeing more of our Fabrication & Welding facilities? Take an interactive 360° virtual tour of Ranken Technical College’s FABRICATION & WELDING TECHNOLOGY department.

Why choose Ranken for your welding courses?

Welding is an essential component of our everyday lives. As a welder, you’ll work on our bridges, our cars and the machinery that makes modern life possible. You’ll be able to use your skills to work in many industries, including building construction, automotive, and manufacturing.

Ranken’s one-year welding certificate program will teach you the essential welding processes you need to get the job you want.

Interested in seeing more of our Manufacturing facilities? Take an interactive 360° virtual tour of Ranken Technical College’s MANUFACTURING departments.

Ranken St. Louis

You’ll get the opportunity to work on the most current and high-tech machinery – our welding courses are held in a 7,500 square foot facility, housing 38 welding booths, a plasma cutting table, a magnetic drill press, two cranes, a shear and a band saw.

Ranken Central MO & Ranken Southeast

Earn money while learning to become a professional welder.

The Fabrication & Welding Day program is designed for students to have 8 weeks of instruction followed by 8 weeks of paid internship for two semesters.

Meeting two nights a week, the Evening program allows working adults access to the same curriculum as the day welding program. Students complete the program after 9 months of hands-on training in our state-of-the-art facility.