Does going to machinist school sound right for you?

You also like to draw and design things – your mind is both creative and analytical.

You want a stable, well-paying career that’s in high demand.

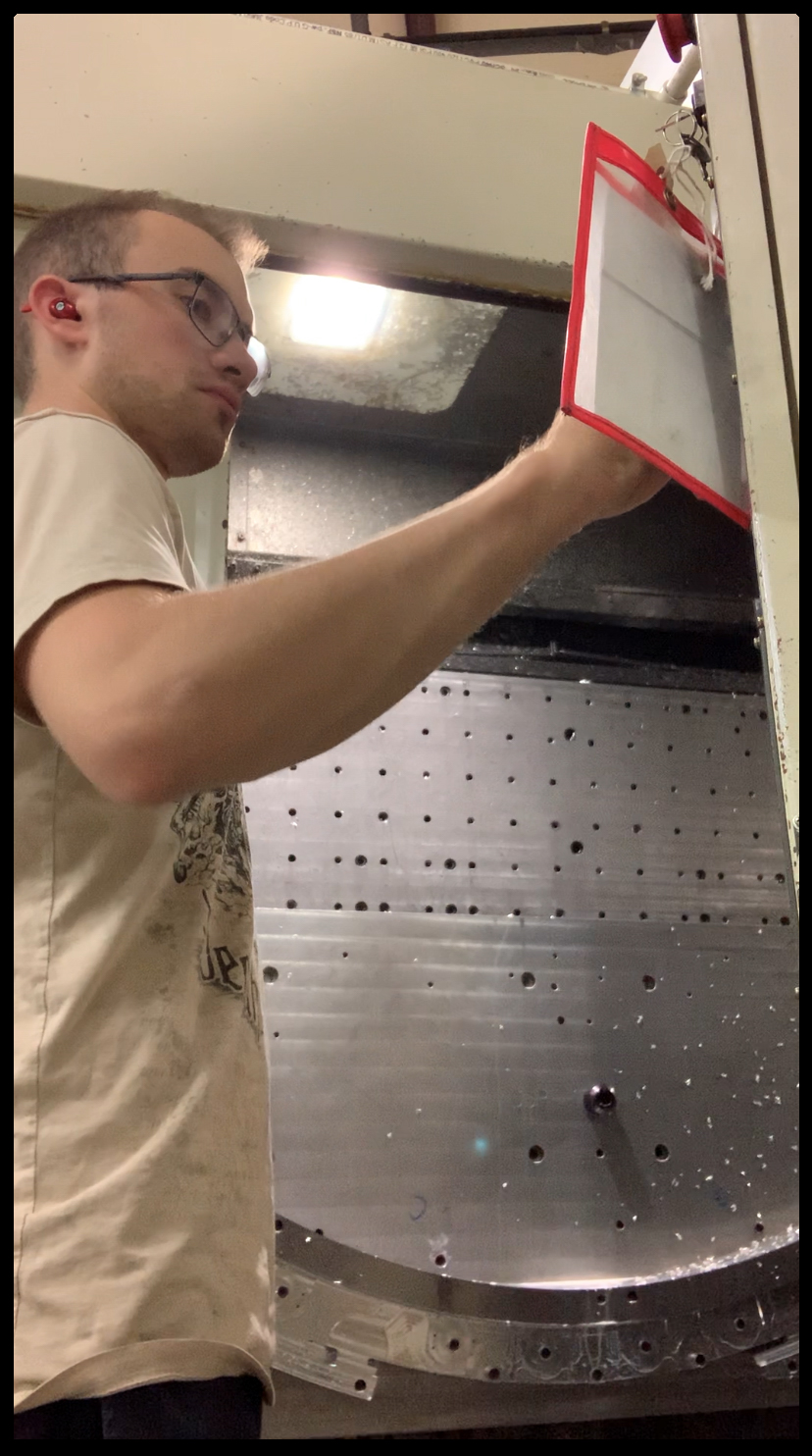

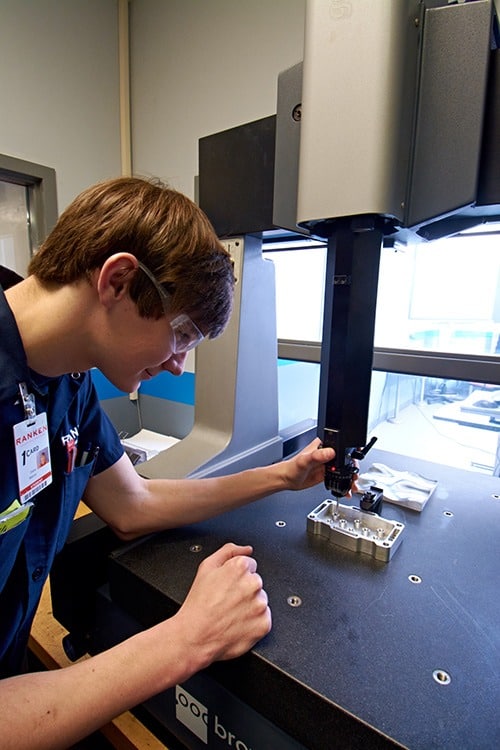

Does this sound like you? If so, Ranken’s CNC machinist training could be the path to a successful and rewarding career. The hands-on experience that you’ll receive is unparalleled in the region.

The use of sophisticated CNC machine tools is increasing rapidly in the manufacturing industry. With the demand for machinists generated by the local defense industry, the St. Louis area is experiencing a shortage of workers trained in the latest technologies. This makes for a great employment outlook for machinist school graduates.

Interested in seeing more of our Advanced Precisions Machining facilities? Take an interactive 360° virtual tour of Ranken Technical College’s ADVANCED PRECISION MACHINING TECHNOLOGY department.

Why choose Ranken for CNC machinist training?

Through Ranken’s Precision Machining Technology (PMT) program, you’ll receive hands-on instruction in the design and construction of operating components for machinery. You’ll be prepared for employment in machining, Computerized Numerical Control (CNC) programming, inspection/ quality control, maintenance and machine tool building.

You’ll learn both the general skills that you need to get started in the field, and you’ll also be trained in specialties including CNC, CAD/CAM, inspection and quality control, engineering design and maintenance machining.

The program follows the standards outlined by National Institute of Metalworking Skills (NIMS), an industry benchmark of manufacturing certification.

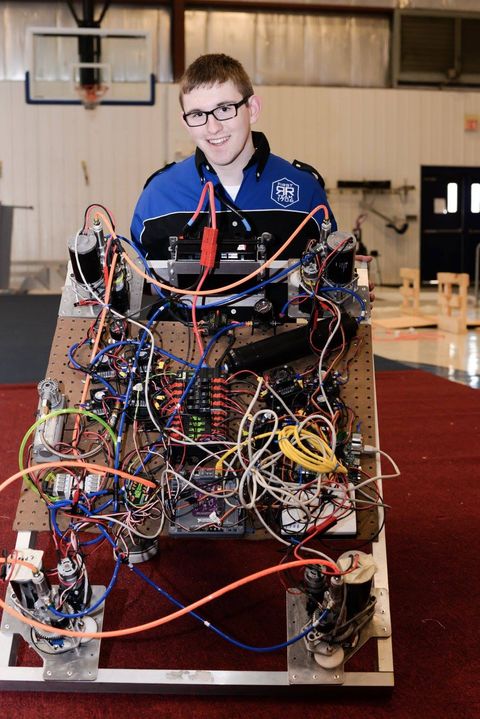

Manufacturers Need Young Talent!

Today’s manufacturing industry is entirely different from what it used to be. It is no longer repetitive, low-skilled work. The industry today is about advanced technologies, state of the art facilities, and fast-paced work environments. Manufacturing holds a place for all types of workers, whether you like to work with your hands or a computer; the growth opportunities are endless. Most importantly, manufacturing is about creating products that affect everyone’s daily lives and even change the world.

Interested in seeing more of our Manufacturing facilities? Take an interactive 360° virtual tour of Ranken Technical College’s MANUFACTURING departments.